Bolt Maritiem - Satellite 44

Vacuum Infusion - Experimental

Before we do the infusion of the part, a few tests are necessary to:

- Get parameters for the simulation

- Verify impregnation of the reinforcement

- Get some hands-on experience with Vacuum Infusion.

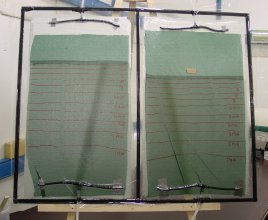

In this case, we were also interested in the influence of continuous fiber mat (CFM). Some say that it improves impregnation of the reinforcement, but there were no clear arguments - at least not convincing enough to make a decision. So we decided to do a test. Because a flow medium is used, there is a big difference between what you see on top and what happens in the reinforcement. This is easy to check visually if you do the infusion on a glass plate.

The setup is straightforward: edge injection of a rectangular strip (using

a spiral at the bottom to supply the resin), put

in vertical position for better visibility and inclusion of gravity

effects (we also did an experiment on a flat table, comparison of results

from both experiments was used to validate the simulations). On top,

another spiral was used for the vacuum. In the pictures you can see the front

and back at (about) the same time. Viewed from the front side (picture above),

the left panel contains just the biaxial and woven glass fabrics while two

layers of continuous fiber mat were added at the bottom (backside) to the

reinforcement in the other panel.

The result is clear: in this particular case, the CFM slows down infusion while it does not improve the impregnation of the reinforcement (note that this is not generally true, but depends on type of foam and reinforcement).

Even though the geometry was simple, working out the results of this experiment analytically is difficult, especially because gravity effects and flow resistance of tubes and spirals have to be taken into account.

With the RTM-Worx flow simulation software however, this is an easy job. The mould geometry is quickly modelled. Starting from initial guesses for the permeability (viscosity was known), we tweaked the value until the filling time matched. From start (input model and properties) to finish (after several simulations and modifications to the model) this took about one hour in total.

With those results, the simulation for infusion of the hull is actually a method to scale the results from relatively simple experiments to the actual product geometry.

home |

applications |

Satellite 44 |

outer skin |

inner skin

© 1997-2022 Polyworx

![[home]](../../../asp/pwxpwx.gif)